PowerWood Conventional Kiln

- 2 kilns at 80 MBF Conventional Kiln

- Can dry to higher temperatures

- Installed in 2021

PowerWood Conventional Kiln

PowerWood Dehumidification Kiln

PowerWood Converted Container Dehumidification Kiln

Wood can be dried by many applications including: Air Drying, Conventional Kilns, Vacuum Kilns, Radio Frequency vacuum Kilns or Steam Kilns.

How dry is dry enough?

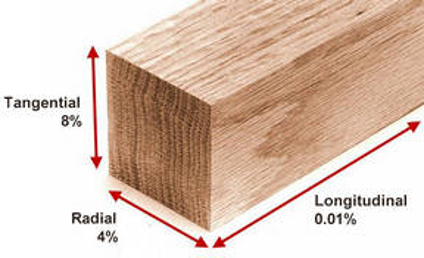

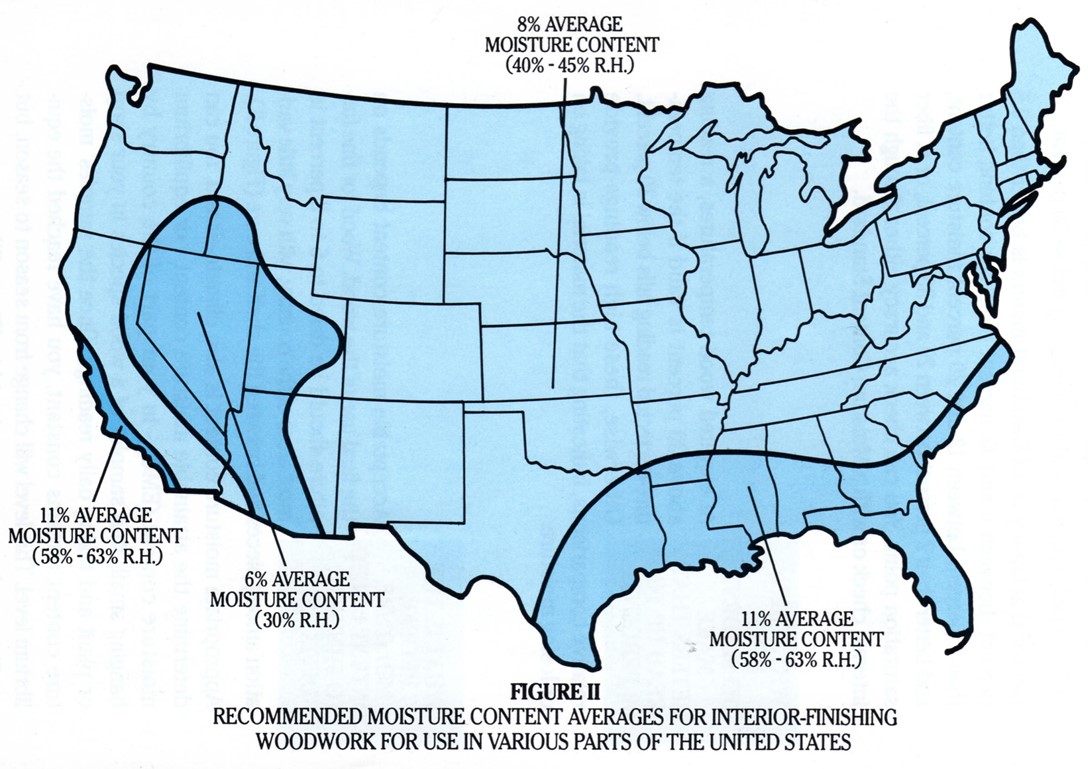

Wood will try to achieve equilibrium with its climate.

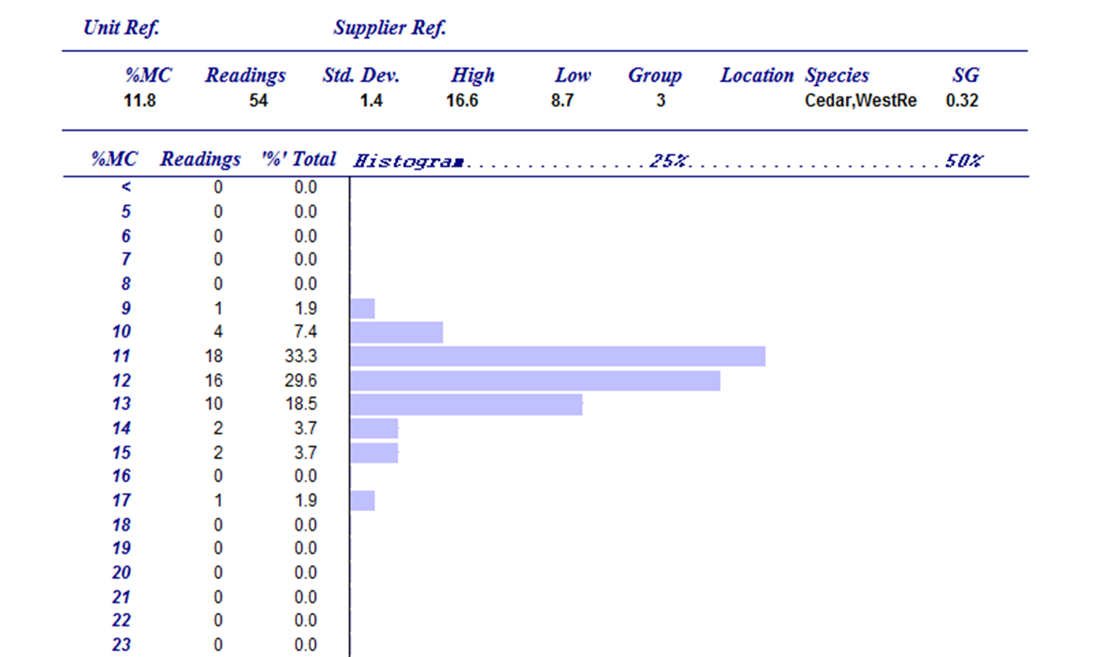

The range is more important than the average – ie: if you are in Phoenix with an average of 8%, it should be good, but if the standard deviation is 3%, you will have many pieces over 10% and those pieces will continue drying to achieve equilibrium – resulting in shrinking and warping.